Not all engines are designed and built the same way. One crucial design difference lies in the structure of the engine block’s top section, known as the deck.

Open deck and closed deck engines represent two distinct designs in this area of the engine. How do these two types of engines differ?

Open Deck vs. Closed Deck Engines: How do they differ?

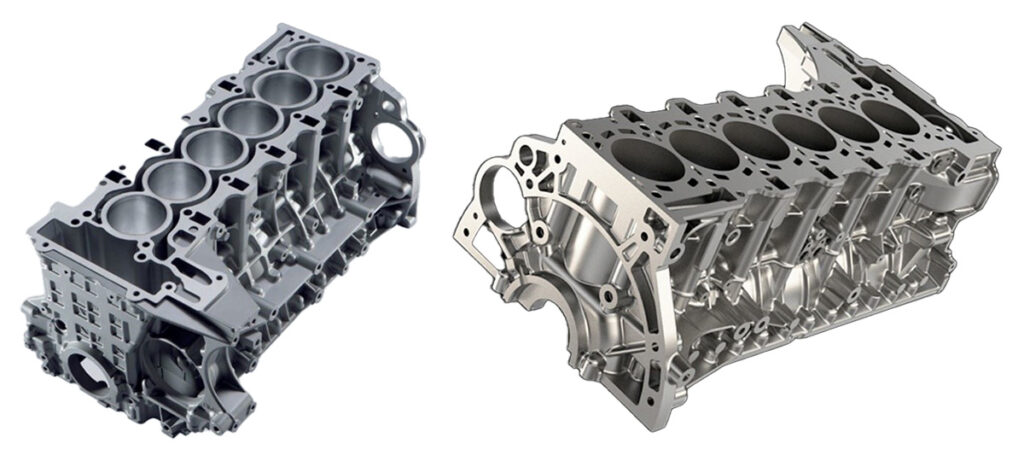

The primary difference between these two engine designs lies in the amount of space between the engine block walls and the cylinders.

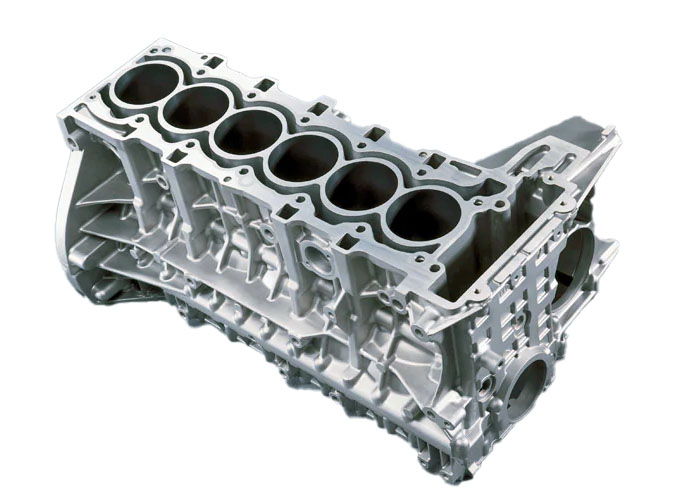

Open Deck:

An open deck engine has a lot of open space between the engine block walls and the cylinder walls, allowing for increased coolant flow and improved engine cooling. Open deck engines tend to be cheaper to manufacture and have better cooling.

Closed Deck:

A closed deck engine has reduced space between the engine block walls and cylinder walls, with only some room for coolant passages. This design gives me engine a more rigid structure, enhancing its strength and its ability to endure higher boost levels.

While a closed deck design remains superior and is often associated with high-performance cars requiring exceptional strength to withstand extreme cylinder pressures, advancements in modern engine design and material engineering have narrowed the gap between open deck and closed deck engines in terms of structural rigidity.

Open Deck Engine Advantages:

1. Reduced manufacturing and development cost

Open deck engines are favored in automotive manufacturing due to their lower raw material requirements and ease of production.

Development costs are also generally lower which means less research and development expenditure for a manufacturer.

Inherently, open deck engine design is dominant these days as it brings down production costs through fewer development expenses and saving on material costs.

2. Cooling system efficiency

The increased clearance between cylinder walls and the engine block enables coolant to flow closer to the combustion chamber, enhancing cooling efficiency.

Coolant can flow directly on the cylinder walls, effectively dissipating heat and maintaining optimal engine temperatures. As a result, open deck engines excel in cooling performance across various driving scenarios.

An open deck engine can perfectly function with a coolant system that would be insufficient for a closed deck engine.

3. Reduced weight

While the weight difference between open deck and closed deck engines is minimal, open deck engines generally feature lighter blocks due to reduced iron or aluminum content. The difference is small; for example, the open deck N55 weighs around ~30 pounds less than the closed deck B58.

However, racing enthusiasts who prioritize weight reduction and a lower center of gravity welcome this advantage. Especially as the engine tends to be one of the heaviest, if not the heaviest part of the entire car.

Closed Deck Engine Advantages:

1. Higher engine block strength

Closed deck engines offer superior structural rigidity, enabling them to withstand higher boost pressures and handle increased stress compared to open deck engines.

The closed deck design provides enhanced support for the cylinder walls, minimizing the risk of catastrophic engine failure under extreme conditions.

Closed deck engines can generally be tuned to levels of power and torque way above factory numbers. It is not uncommon to see closed deck engines tuned to make twice or even three times the amount of their stock horsepower, making them a popular choice for performance or tuning-oriented applications.

2. Better long-term durability

The reinforced structure of closed deck engines, particularly between the cylinder walls and the block, ensures long-term durability and reliability. The increased metal mass enhances the engine’s structural integrity, allowing it to withstand prolonged heat and sustain high levels of strain.

Closed deck engines outlast comparable open deck engines, making them a preferred choice for demanding scenarios

3. Better for the track and high-demanding applications

Closed deck engines excel in scenarios that involve prolonged exposure to high levels of stress, making them ideal for built racing engines.

While closed deck engines may not offer the same cooling efficiency as open deck engines, they are specifically designed to handle the demanding conditions of track racing and other high-performance applications.

The structural strength and durability of closed deck engines make them capable of enduring prolonged heat and maintaining their performance even under extreme strain, such as track use.

Semi-Open Deck Engine

In addition to open deck and closed deck designs, there is a middle ground known as semi-open deck engines. These engines combine aspects of both designs to create a balance between structural rigidity and cooling efficiency

A semi-open deck engine features large openings like open deck engines but adds additional support, known as bridges, in specific areas throughout the openings.

This design allows semi-open deck engines to handle higher pressure levels than open deck engines while sacrificing some cooling efficiency. Subaru often employs semi-open deck designs in their engines.

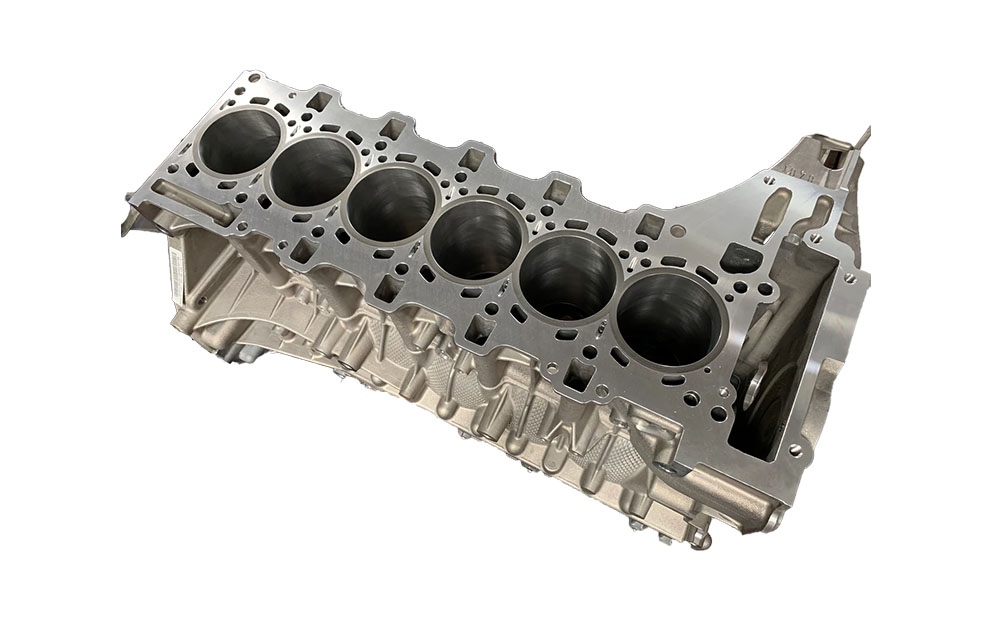

Well-known Open Deck Engines:

- BMW N54 – The N54 engine is a 3.0L twin-turbocharged six-cylinder engine. Even though it uses an open deck design, it is still popular with tuners and is known to be able to push more than 600hp on a stock engine block with stock internals.

- BMW N55 – The N55 engine replaced the N54 and is also a 3.0L turbocharged six-cylinder engine. It uses an open deck engine design. A stock block N55 can push up to 550hp.

- BMW N20 – The N20 engine is a 2.0L 4-cylinder turbocharged engine later replaced by the BMW B48. In contrast to the B48, the N20 features an open deck design.

- BMW N52 – The N52 is the successor to the BMW M54 and also uses the same 6-cylinder configuration, with a displacement between 2.5L and 3.0L. Despite being an open deck engine, the N52 is known as a dependable, under-stressed engine.

- Nissan VQ35DE – One of the best performance engines in the early 2000’s. This engine powered the 350z among other Nissan vehicles.

Well-known Closed Deck Engines:

- BMW B58 – The B58 replaced the N55 and is also a 3.0L straight-6 with a single twin-scroll turbocharger. With stock internals, the B58 can withstand more than 750hp.

- BMW S58 – A new M Performance engine powering the G80 M3 and other M-cars. It is the successor to the S55, and it also features a closed deck.

- BMW B48 – The B48 is part of BMW’s new modular family of engines. It is a 2.0L 4-cylinder single turbo engine powering most of BMW’s lineup.

- BMW S63 – The famous S63 engine is a 4.4L twin-turbocharged V8 used on many BMWs top-spec large M cars such as the M5. With a closed deck design and an appetite for destroying tires, the S63 offers between 547hp and 617hp. With stock internals, the S63 can output well over 800hp.

- BMW S85 – This gloriously-sounding 5.0L naturally aspirated V10 is found in the 2005-2010 BMW M5 and M6. With exactly 500hp on tap, the S85 is one of the most exciting, but difficult to live with BMW engines.

- Toyota 2JZ-GTE – One of the most iconic engines of all time. A turbocharged straight-6 capable of making over 1000 hp on stock internals. It is no surprise that this engine has a closed deck design.

- Nissan RB26DETT – Another well-known Japanese engine from the late ’90s. This engine powered the R34 Nissan Skyline GT-R.

Open Deck to Closed Deck Conversion

While it is technically possible to convert an open deck engine into a closed deck engine, the process is complex and requires precision machining and modifications.

One method involves filling the block with epoxy filler, but this approach is not guaranteed to result in a functional engine.

Coolant flows must be rerouted, and there are many additional considerations such as heat expansion, the melting point of the filler material, etc.

A more effective method is using a CNC machine to cut the area around the cylinders and install precision-cut plugs or inserts.

This process also involves machining components such as coolant ports onto the deck. It is recommended to consult with experts or engine builders for such conversions.

Frequently Asked Questions

Are open deck engines weak?

Not necessarily. While open deck engines may be comparably weaker than closed deck engines when comparing identical engines, advancements in materials, precision machining, and overall manufacturing have greatly improved the strength of open deck engines.

Modern open deck engines, especially turbocharged ones, are remarkably strong. Employing a closed deck design is one of many different ways to make an engine stronger.

For example, the BMW N54 engine, despite being an open deck design, has proven to be an incredibly robust and capable engine block that can handle high boost pressures for high horsepower outputs.

Are closed deck engines better?

If you want an excellent performance engine capable of receiving continuous abuse, yes, a closed deck design is better. Closed deck engines can be more easily tuned and usually withstand higher power and boost pressures. From stock, a closed deck engine has a much higher power/pressure ceiling compared to an open deck engine.

Conclusion & our thoughts

Automotive engineers have made significant strides in perfecting internal combustion engines. Open deck and closed deck designs represent two different approaches to engine construction.

While closed deck engines generally offer superior strength and durability, open deck engines can provide excellent performance and power capabilities.

The N54 for example is an open deck engine capable of putting out impressive performance figures way above the factory numbers.